This is new version to do maximum 300mm width wet wipes with 5-8-10-12-16-20 lanes according to your actual production requirement.

2026 New version Fully automatic 5 lanes 300mm width small rolls antibacterial baby wet wipes making complete line

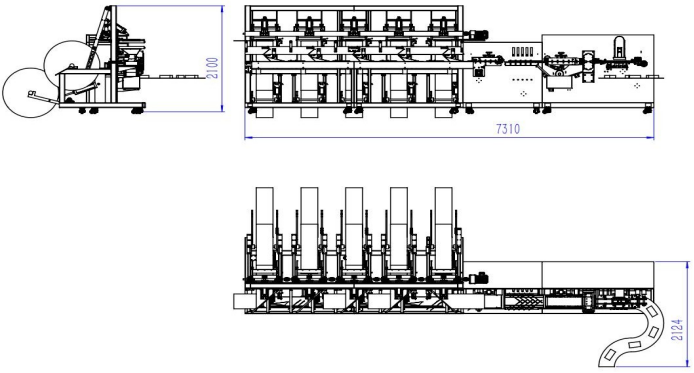

CW-2700-5-300 Fully automatic Baby Wipes Folding Machine

1. Product type: baby wipes, cosmetic wipes, ladies wipes and cleaning wipes.

2. Production speed: (400 cuts-500 cuts/minute, 35-45 per pack of 60 pieces per minute)

3. Applicable material: spunlace fabric

4. Material weight: 40-60 g/m2

5. Voltage: 380V 50HZ

6. Power: 13KW

7. Raw material roll width: 220-300mm

8. Unfolded size (mm): (220-300) × (90-240) MM (L×W)

9. Folded size (mm): (100-110) × (90-240) MM (L×W)

10. Folding method: "Z" type

11. Humidification system: double mixing barrels with agitator.

12. Installation space (m): 10×3×2.4 (L×W×H)

13. Bucket size (mm): 900 x 900 x 1900

14. Machine weight: 9T

15. Production efficiency: >=85%

1. Semi-servo design, scientific and compact structure, easy to operate and maintain.

2. Designed according to CE standards, with safety protection door, emergency stop and related protection systems.

3. The main mechanical parts are made by CNC machining center, and the main electrical components are world famous brands.

4. Transmission, universal joint, gearbox and phaser, rear drive belt.

5. Phase adjustment is synchronized with the machine.

1. Steel structure, stainless steel plate and stainless steel parts.

2. Extraction or non-extraction can be adjusted.

3. Tube spray type liquid addition is adopted. .

4. The liquid addition system includes continuous stirring system, circulation system, and adjustable liquid addition amount. The maximum liquid addition flow rate is 20 liters/minute.

5. Liquid addition system accessories: The pipeline adopts stainless steel pipe and some transparent hose.

6. The stacking system makes the folded materials flat and consistent.

7. Raw material cutting system, the length is adjustable.

8. The sheet number and stack number counting system adopts servo motor to easily adjust the quantity.

9. Transmission system.

10. Host human-machine interface.

11. Finished product output.

12. The electrical parts are all CE certified.

13. Safety protection system: emergency brake system, blade safety, glass door protection.

14. Xinjie servo system

15. Human-machine interface color touch screen.

16. Automatic alarm for material shortage.

17. Automatic counting.

18. Automatic recording of production date.

1. Driving mode:

Adopt servo motor and Xiamen ordinary motor. The driving shaft adopts coupling.

The rear drive uses synchronous belt and synchronous wheel. Wide synchronous belt is used at high tension.

2. Control system:

Xinjie PLC control system and monitoring system. Electric eye monitoring.

Automatic control function

3. Operation mode: human-machine interface, menu operation, each data is easy to modify and adjust.

Automatic tracking and monitoring of raw materials: any material breakage and shortage will automatically stop in the shortest time to reduce loss.

4.Xinjie electrical control system: main circuit system, secondary circuit system and tension control system, PLC control system and other auxiliary systems.

5. Product output: imported conveyor belt is used. The friction force is adjusted according to the speed to ensure the good operation of the assembly line.

1. Wide steel plate is used for the conveyor belt base.

2. Rust-free and long-life shearing knife is used.

3. The main electrical components are CE certified.

4. The main components are famous brands.

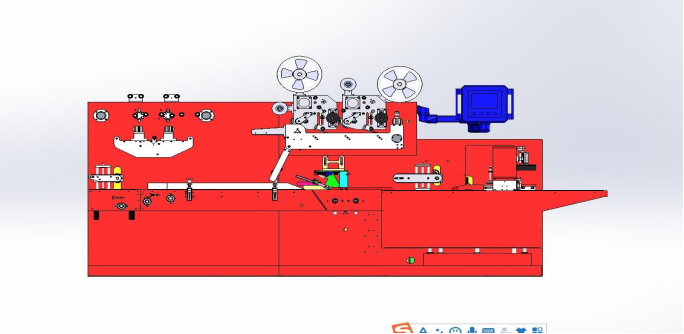

CW-B3900 Fully Automatic Baby Wipes Packaging Machine

1. Packaging film, width ≤ 420mm, diameter ≤ 400mm

2. Label, width ≤ 60mm, diameter ≤ 300mm

1. Mechanical packaging film tension control device.

2. Packaging film skylight device.

3. Two sets of labeling devices. Both sets can be used at the same time, or one set can be used alone.

4. Packaging film forming device.

5. Packaging film longitudinal sealing device.

6. Packaging film transverse sealing device. Servo drive.

7. Film feeding and transverse sealing servo drive. The servo motor automatically runs synchronously.

8. The electrical control mode has two modes: automatic and manual. To meet the needs of production process control.

9. Each motor can be started and stopped separately. Operate on the touch screen.

10. There are 2 emergency stop buttons spaced along the length of the whole machine.

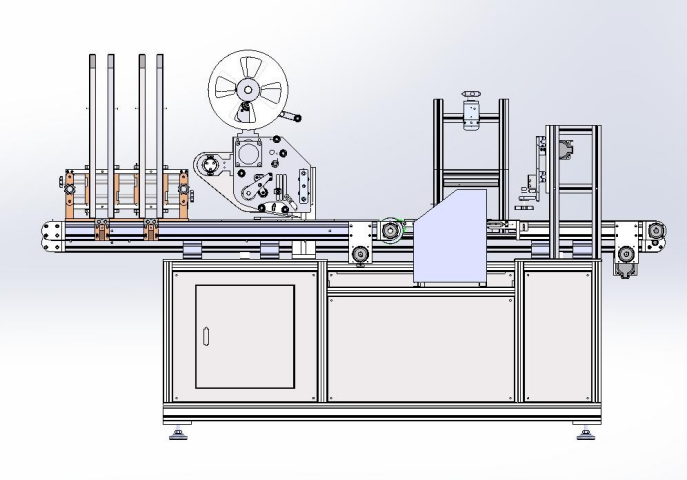

CW-2900-II Fully automatic baby wipes capping machine

1. Power supply: three-phase 220V, 50Hz

2. Power: about 5KW

3. Design speed: 50 packs/minute

4. Production speed: 40-45 packs/minute

5. Cover (mm): width ≤80, length ≤120

6. Label (mm): width ≤60, diameter ≤300

7. Material: plastic cover and label, hot melt adhesive

8. Machine size (mm): 2600*1000*1660 (length*width*height)

9. Servo motor control + vision + cover deviation correction control + automatic labeling control + automatic gluing

1. 2 cover slots

2. Synchronous belt cover feeding mechanism (servo control).

3. One labeling machine, automatic stop when no cover.

4. Servo automatic cover removal and cover application robot.

5. Customized plastic box.

6. Guide mechanism.

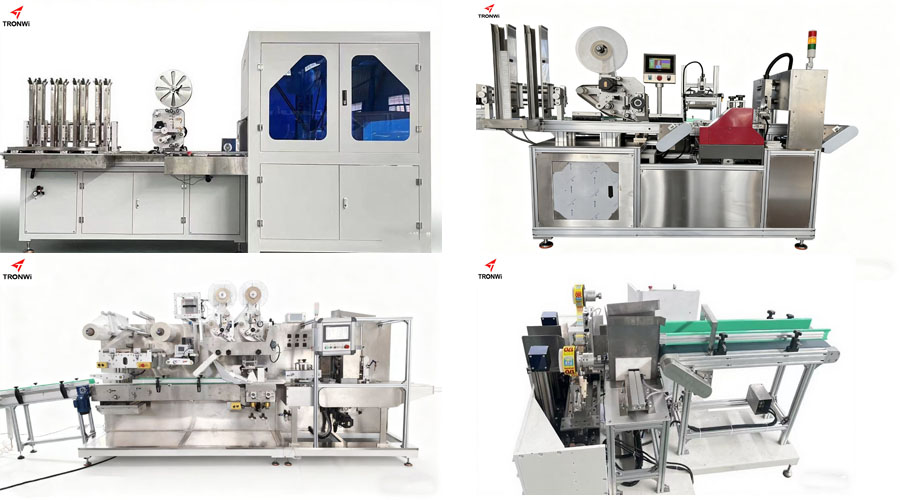

Other popular machines

Customers cases

Delivery cases

Certificates

Contact information

WeChat WhatsApp

Manager: Mr. Michael Chou

E-mail: info@tronwi.com

Website: www.tronwi.com

Wechat/WhatsApp: +86-18659050717

Telephone: +86-18659050717

Facebook: www.facebook.com/tronwimachinery

Skype: 1023942283

Address: No.770, Nanhuan Road,Licheng District, Quanzhou City, Fujian Province,China.

Contact: Mr.Michael Chou

Phone: +86-18659050717

E-mail: info@tronwi.com

Add: No.770, Nanhuan Road,Licheng District, Quanzhou City, Fujian Province,China