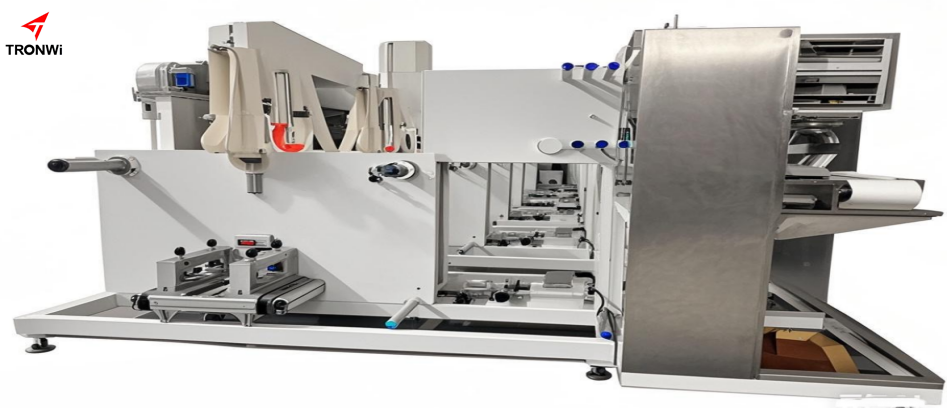

New design 12 lines left and right single roll baby wet wipes production line

12 lines fully automatic baby wet wipes left and right single roll automatic splicing mechanism production line

Baby wipes 30 pcs-120 pcs fully automatic production line

Production process: Single roll of non-woven fabric raw materials---one roll on each side---one group running and one group on standby---folding----liquid preparation----liquid addition----length cutting----pieces stacking----complete palletizing product output----buffer conveying mechanism----entering the packing mechanism----ensure that each package is positioned and the push rod is conveyed to feed----packaging materials----printing date-----hole punching-----labeling----film forming----product cutting and packaging----packaging finished product output----covering mechanism----4-station rough material mechanism----two groups running, two groups on standby----cover pushing----cover feeding----labeling-----gluing----visual control pasting----finished product output.

Metal and weigher detector

CW-SL-12-01 Fully Automatic left and right Roll Wet Wipes Folding Machine (12 lanes)

Main technical parameters:

1. Product type: baby wipes, cosmetic wipes, ladies wipes, cleaning wipes

2. Design speed: 600 cuts/minute (double blades)

3. Speed: 400-550 cuts/minute, (depending on the length of the material)

4. Number of pieces per package: 30-120 pieces/package

5. Applicable materials: spunlace non-woven fabrics, biodegradable materials, hot air cloth

6. Raw material weight: 35-100g

7. Working voltage: 380V 50HZ

8. Power: 20KW

9. Machine weight: about 10T

10. Raw Material Width (mm): 800-1200mm, Maximum Diameter 1000mm

11. Unwind Stand

12. Number of Parent Rolls: 24 rolls of base paper

13. Unwind Reels: 24-roll pneumatic reels

14. Parent Roll Specifications: 150-300mm, Maximum Diameter 1000mm

15. Material Rewinding: Low-material warning light, automatic or manual rewinding with no machine stop

16. Post-Unwind Traction Device: Smooth traction shaft surface for low friction

17. Material Sensor: Low-material detection sensor, low-material alarm

18. Number of Lanes: 12

19. 12 sets of Folding unit.

20. Material shelves: 6 sets (each set has 2 rolls of raw material, with 4 rolls per set, two rolls for production and two rolls for spare preparation).

21. Unfolded dimensions (mm): (110-300) x (140-300) (Length x Width)

22. Folded dimensions (mm): (110-300) x (90-120) (Length x Width)

23. Folding Type: "Z" or "N" pop-up or non-pop-up (adjustable), capable of producing single stacks of 12 sheets, with continuous draw-out

24. Counting Method: Automatic counting, automatic adjustable stacking system

25. Automatic Feeding Mechanism: Pneumatically cuts off the material feed

26. Wetting System: Quantitative dosing system, double tanks with agitators, 600L double tanks and three pumps

27. Human-Machine Interface Control

28. Process parameter and recipe storage for easy retrieval and modification of specifications

29. Low-material alarm, material outage shutdown Automatic material handling, water level monitoring and alarm.

30. Electronic control: Delta system and Delta servo motor.

31. Emergency stretching stop switch.

32. Recipe storage for easy check.

33. Metal and weight detection with automatic waste discharge.

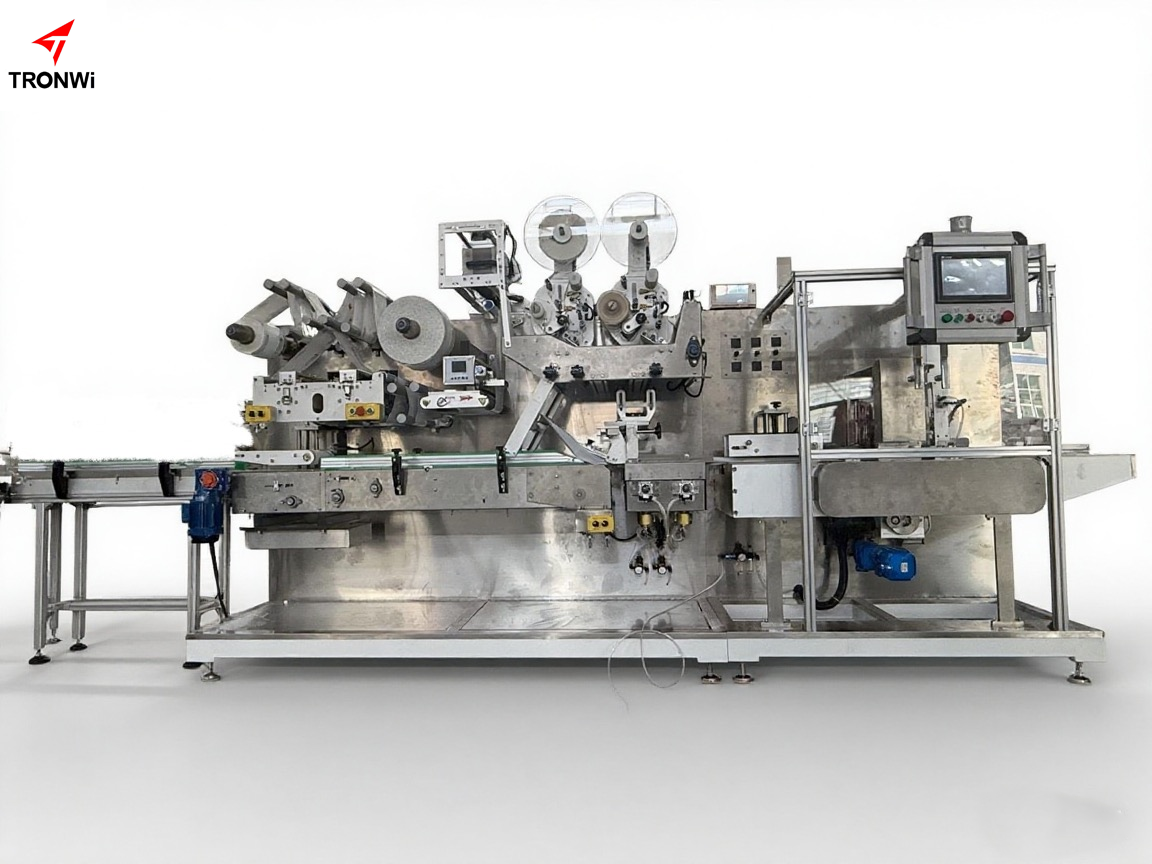

CW-WF80 Fully Automatic Wet Wipes Packaging Machine

Main technical parameters

1. Packaging materials: ET/PE BOPP PET/AL/PE and other heat-sealing materials.

2. Film core diameter: 3" (76.2mm) international standard.

3. Film roll number setting: 2 film rolls. One roll is running and the other is on standby.

4. Film specifications: maximum width 450mm, roll diameter <360mm

5. Packing size: L150-380mm W80-140mm H10-100mm

6. Applicable labels: transparent labels, opaque stickers (metal foil labels are optional)

7. Roll number setting: 2 labeling devices (can run simultaneously or automatically switch running)

8. Label size: L50-150mm W20-90mm

9. Naked eye size: L10-70mm W10-50mm

10. Design speed: 80 packs/minute

11. Production speed: 40-75 packs/minute

12. Working voltage: AC380V, 50/60HZ

13. Power: 28KW

14. Air consumption: 0.6-0.8Mpa

15. Machine size: L5045mmx W1211mmx H2116mm

16. Machine weight: about 15,000 kg

17. Electronic control: Delta full servo drive

18. System: Delta motion control system

19. Date: ink wheel printer

20. Deviation corrector

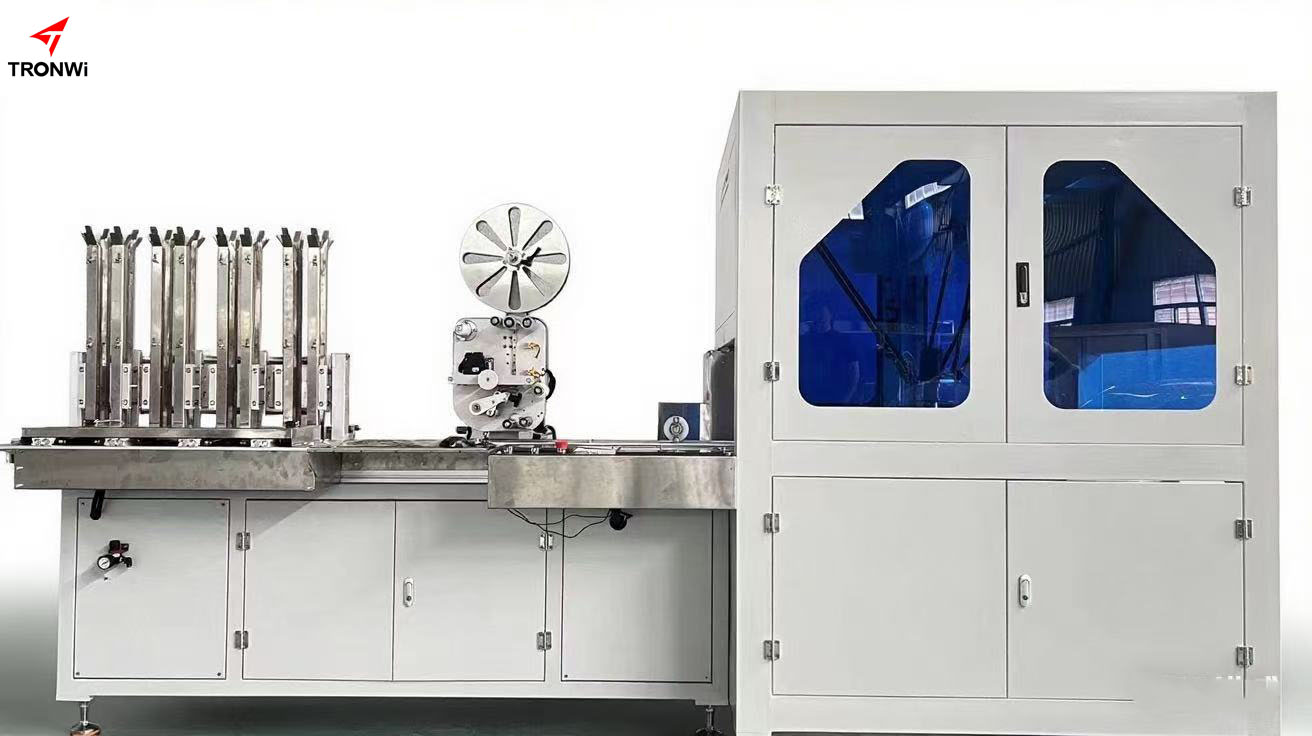

CW-ASD750 Fully automatic Robot Hand Wet Wipes Capping Machine

1) Main technical parameters

2)1. Speed: 80 packs, 65-75 packs per minute stable

2. Control system: touch screen + PLC + Panasonic full servo + Yiyi system

3. Label size range: length 50-100mm; width 40-100mm

4. Finished wet wipes: length: 50-300, width: 50-200mm, height: 20-120mm.

5. Applicable types: various specifications (the switching time between models can be controlled within 2 minutes.

6. Cover size range: length 50-200mm, width 50-120, height 2-10mm Acceptance standard: +1mm

7. Scrap rate: 1%

8. Wet wipes cover capacity: 4 storage slots

9. Computer monitoring, real-time monitoring of the moving process, one-key input, to achieve product switching

10. Working voltage: DC24V:2220V/50Hz; Power: 8KW

11. Machine size: 3300×1200×2000mm (L*W*H)

12. Process parameter formula storage, convenient for specification replacement and modification

Contact information

WeChat WhatsApp

Manager: Mr. Michael Chou

E-mail: info@tronwi.com

Website: www.tronwi.com

Wechat/WhatsApp: +86-18659050717

Telephone: +86-18659050717

Skype: 1023942283

Address: No.770, Nanhuan Road,Licheng District, Quanzhou City, Fujian Province,China.

Contact: Mr.Michael Chou

Phone: +86-18659050717

E-mail: info@tronwi.com

Add: No.770, Nanhuan Road,Licheng District, Quanzhou City, Fujian Province,China