Single Pouch Automatic Folding and Packing Machine For Wet Wipes with good Quality and price.

CW- DP400 Fully Automatic High Speed Single Wipes Folding and Packing Machine

1.Product Parameters

| Product Type | Disinfectant Wipes , Cosmetic Wipes , and Cleansing Wipes |

| Design speed | 450 pieces/minute |

| Production speed | 250-400 pieces/minute (depending on the material) |

| Number of pieces per pack | 1 piece/pack |

| Applicable materials | spunlace non woven, degradable materials |

| Material weight | 35 -80 grams/m2 |

| Packaging film thickness | 0.025mm -0.065mm |

| Working voltage | 380V 50HZ |

| Power | 10KW |

| Raw material roll width | 150-300mm |

| Unfolded size (mm) | ( 160-260) x ( 150-300) ( L x W) |

| Folded size (mm) | (80- 130) x (50-85) ( L x W) |

| Packaging film | PE & PET, OPP & PE (aluminized film), OPP & CPP, PE T& CPP (aluminized film) |

| Packing bag size (mm) | ( 100-200) x (60-80) (L x W) |

| Folding way | "Z", "W" |

| Humidification system | Mixing bucket with agitator, spray, soaking mode can be switched |

| Liquid storage tank | 400L |

| Machine size (mm) | 6000× 1100× 1700(L×W×H) |

| Tank size (mm) | 800x 900 x 1500 |

| Machine weight | 2500kg |

2.Product Description

1. Scientific design, compact structure, easy operation and maintenance.

2. The main mechanical parts are made by CNC machining center, and the main electrical components are famous brands.

3. The electric heating part automatically controls the temperature.

4. Rear drive belt

5. Phase adjustment is synchronized with the machine.

6. The spunlaced fabric is unrolled in the center, and the material is automatically spliced.

7. Use the tube spray type to add liquid, and the soaking mode to add liquid.

8. The liquid addition system includes a continuous stirring system and a circulation system, and the amount of liquid addition can be adjusted.

9. Raw material cutting system, the degree can be adjusted by touch screen.

10. Non-woven fabric, packaging film has its own deviation correction function.

11. Host man-machine interface.

12. Packaging film tension control.

13. Coding system, deviation correction system (Spunlace nonwoven and film).

14. The packaging is formed, the size can be adjusted, and the width can be replaced with abrasive tools. (If you need different sizes, you need to customize and replace the molder)

15. Middle sealing system: traction preheating, longitudinal sealing heating.

16. Horizontal sealing system: independent mechanical cam control.

17. Finished product output.

18. Safety protection system: emergency braking system, blade safety, plexiglass protection.

(3) System features

1. Drive mode: Delta servo control system.

2. The drive shaft adopts a coupling.

3. Timing belt for rear drive.

4. Control system: Delta control system.

5. PLC control system and monitoring system.

6. Automatic temperature control: Each part adopts independent digital temperature indication, and the data can be set according to different usage conditions.

7. Electrical control system: main circuit system, secondary circuit system, temperature control system and tension control system, PLC control system and other auxiliary systems.

8. Product output: Conveyor belt is adopted. The friction force is adjusted according to the different speeds to ensure a good assembly line.

9. Using aluminum alloy life cutter.

10. The main electrical appliances have passed CE certification.

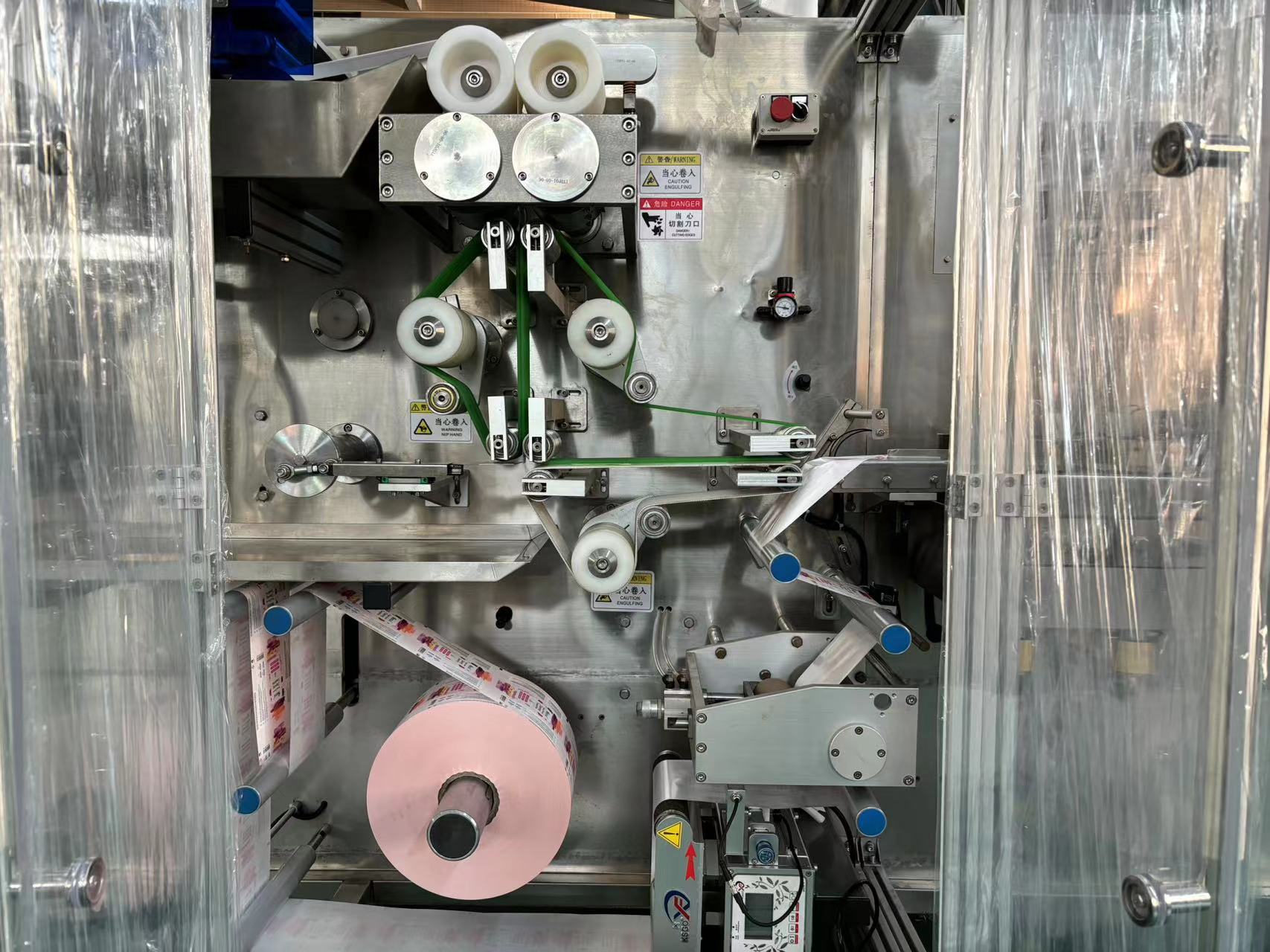

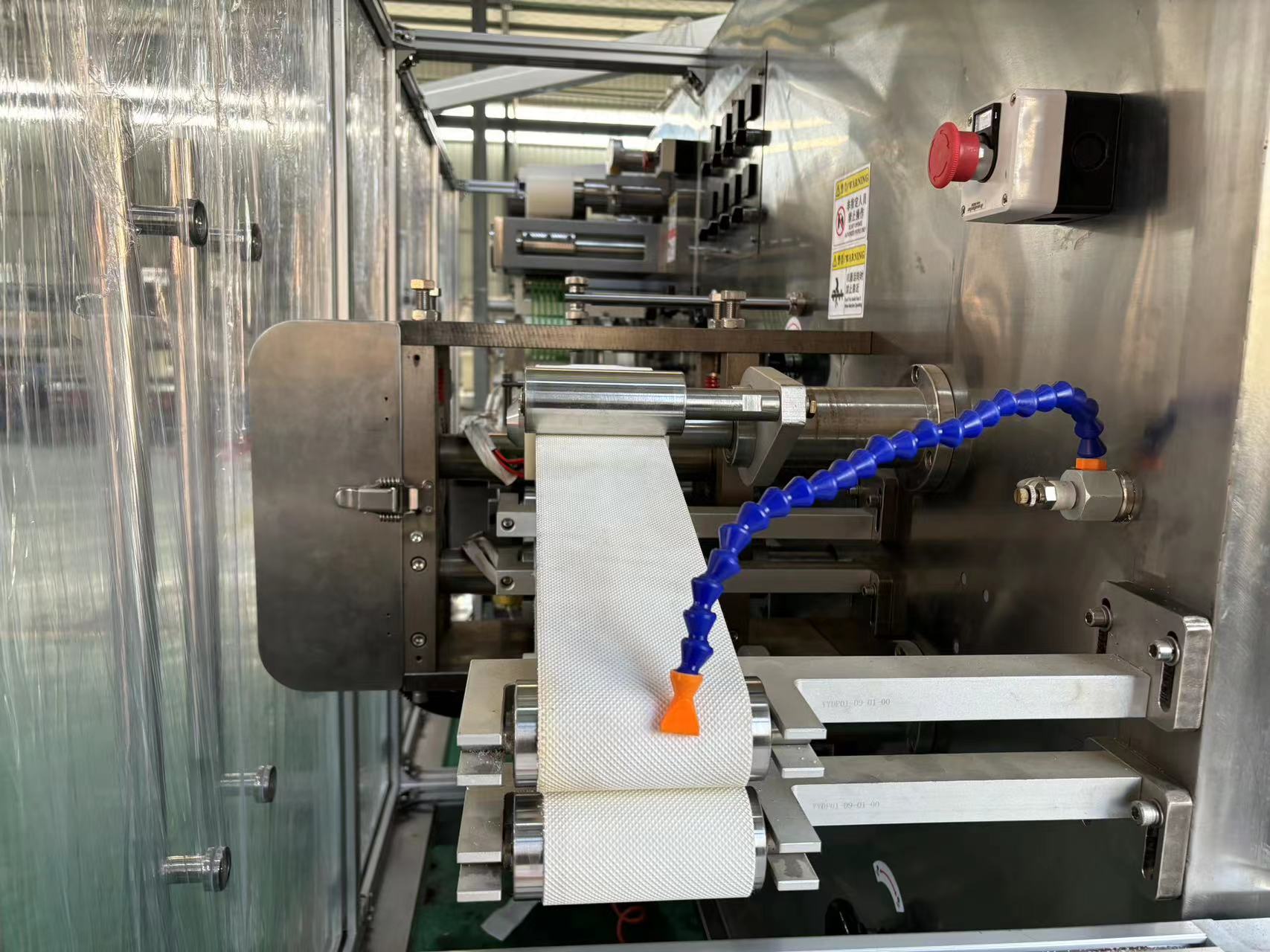

3.Machine Photos

4. Factory shows

Contact information

Contact: Mr.Michael Chou

Phone: +86-18659050717

E-mail: info@tronwi.com

Add: No.770, Nanhuan Road,Licheng District, Quanzhou City, Fujian Province,China